|

| Click on any image for a larger view. |

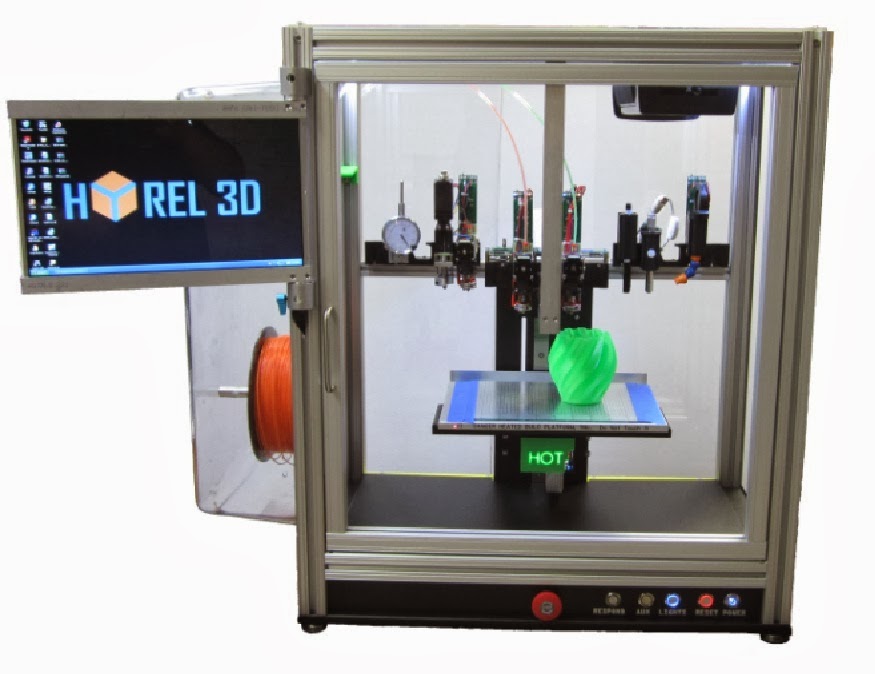

A couple of colleagues in my neck of the woods were curious how we clean our nozzles. As you can see in the image above, this one is pretty clogged, but it was still working. In the past we have had our metals teacher next door use a low temperature torch to melt the filament out of the nozzle but we are always concerned about getting it too hot and altering the size of the opening at the tip.

When we had issues with the Afinia printer, their support crew described a way to clean them so we gave it a try. So...here's how we do it now;

The image above shows our complete set up. We took an out of service wood burning iron (tip was broken off in the end of the iron) and clamped it in a screw clamp so it would stand up. Set the tip on the end of the iron and let it get hot. Afinia support suggested that we heat the tip in the extruder head then quickly remove it when it reached operating temperature but after checking the operating temps of the wood burner, we settled on doing it this way as it reaches similar temperatures as the extruder heaters on the machines.

We pour a little acetone in the can and when the tip has heated for a while we drop the tip into the can and let it soak for a while. BEWARE!!! Acetone is very toxic and the fumes created when you drop the hot tip into the can are no exception. You need to be sure and have VERY GOOD VENTILATION!!! Don't breath this stuff and don't get it on your skin!!!

After the tip has soaked in the acetone for a bit, we take it out and blow the tip out with compressed air. Hang onto the tip or it will go flying across the room! We repeat this process until the tip is acceptably clean.

As you can see here, the interior is free of filament and you can see that the tip itself is completely open. Works for us!